Makerfabs Daily Bad Operation in PCBA Cleaning

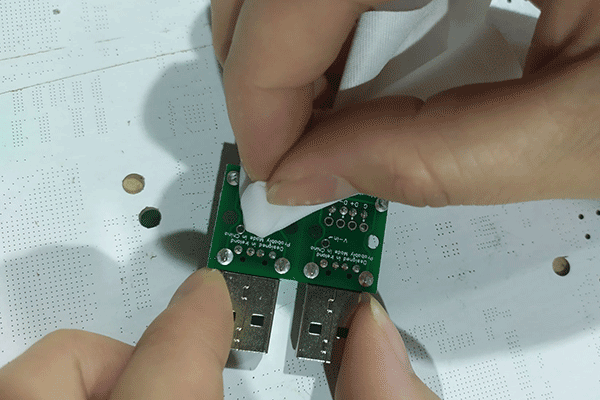

Makerfabs deal with more than 100 PCBA projects per month, this time we would like to share the daily work in PCBA manufacturing: bad operation occurred on PCBA cleaning.

1. Why need PCBA cleaning and how?

There more than 100 PCBA projects Makerfabs deal with per month, from PCBA prototyping a few pcs to mass production a few thousand. But, life is not easy…

Yesterday, we come across another big problem in PCBA manufacturing, which we would like to share here, for a record and also reference for other PCBA producers.

The problem occurred on PCBA cleaning.

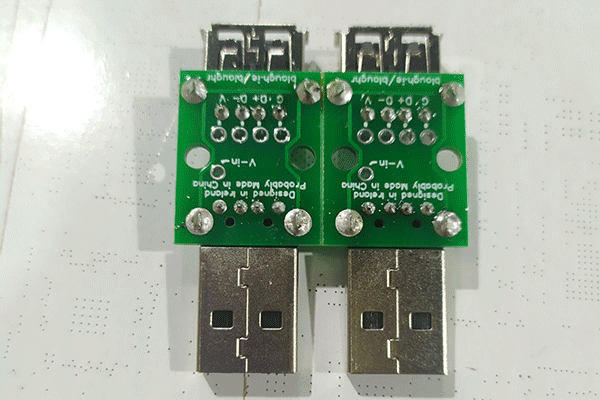

As most of our customers will sell the boards as bare PCBA to the end-users, or use the PCBA in projects without a case, Makerfabs always make the boards clean after the soldering work.

For PCBA production, there would be some kind of “oil” (actually rosin) on the PCBA surface, especially after the THT soldering work, besides, there could be also some tin slags, which is dangerous in usage.

Normally in visual checking, we use brushes/ non-dust cloth with the detergent (mainly Hydrocarbon and ethanol, normally we called it: washing water) to clean the boards.

2. Problems we met in PCBA cleaning and some suggestions

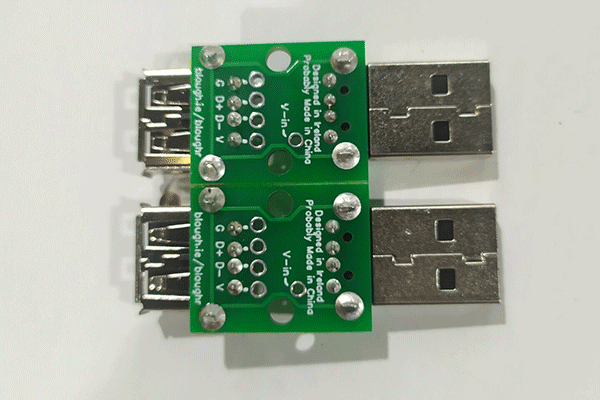

This is not an easy work as it looks like, yesterday, one of our workmates made such a mistake in PCBA board cleaning.

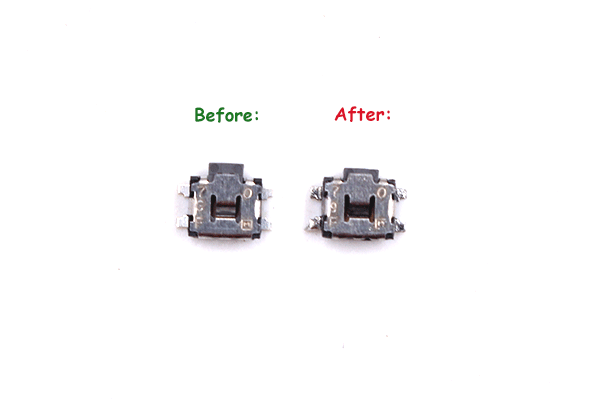

This is a tiny push-button, with plastic parts inside. He ignored this~~ that is, the washing water will corrode the inside plastic parts. We finally found that more than 20% of buttons do not rebound back when pressed.

Solution: Replace all the tiny buttons from the PCBA boards, which will take extra 2 working days.

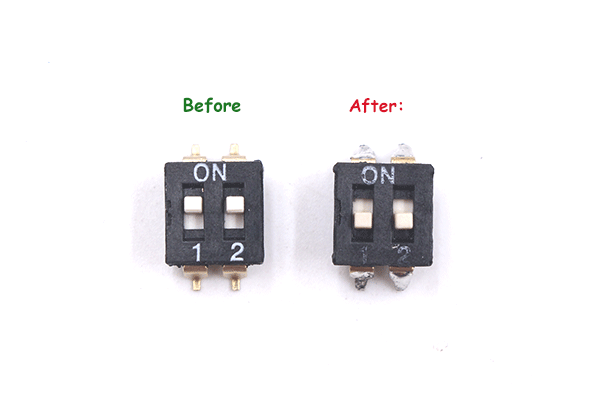

And, we found this switch encountered the same problem. It gets very tight to switch back and forth if you clean it with washing water. And we have to also replace them all.

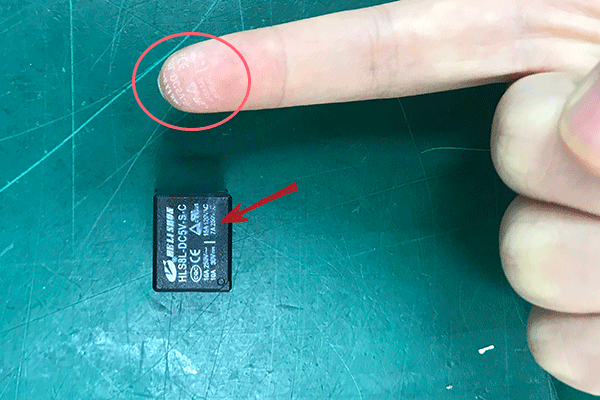

And by the way, kindly reminds, from our previous experience in PCBA manufacturing: DO NOT make the relay touch the washing water, even a finger with wash water will make a fingerprint on the surface:

Previous

Previous