Makerfabs Daily: Solving the OLED Sticking Problem

Makerfabs Daily: Solving the OLED Sticking Problem

Yes, again, we got some problems in a round of circuit board production, for the OLED sticking problem.

After the PCBA testing, Makerfabs help to stick the OLED on the PCBA board with stickers. We did this manually. But this lead to another unexpected problem, after Makerfabs handed over all the boards to the final assembly factory, we got their feedback: The OLED is not stuck right, and there almost none of them are OK for the product assembly. Nightmare~!

To cooperate better, we asked the product assembly factory to send all the PCBA back to us, to check the reason for OLED Sticking.

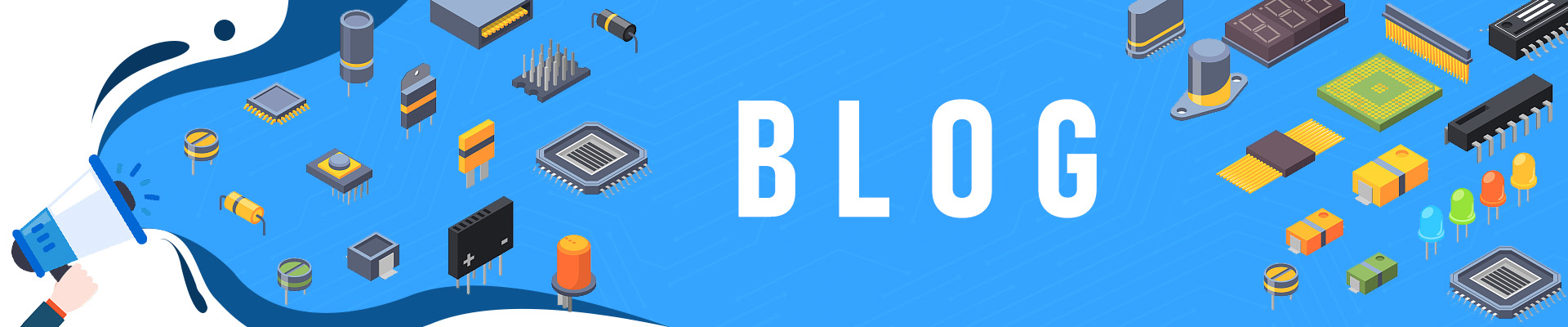

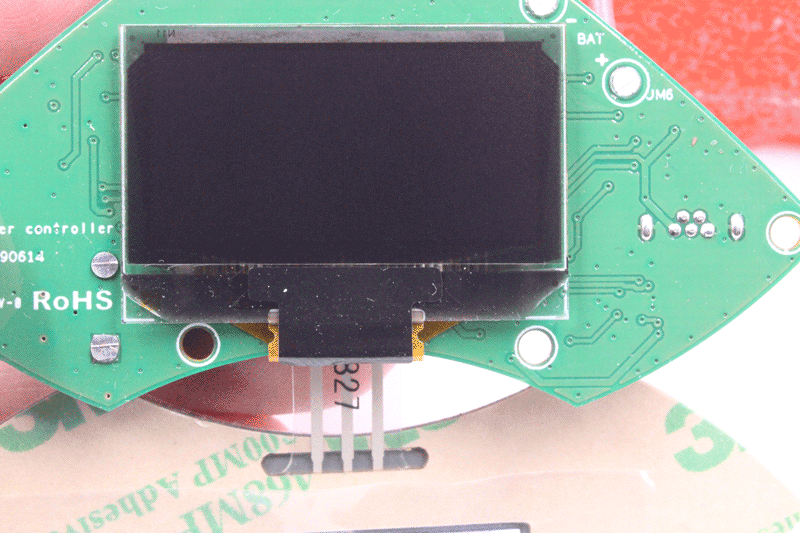

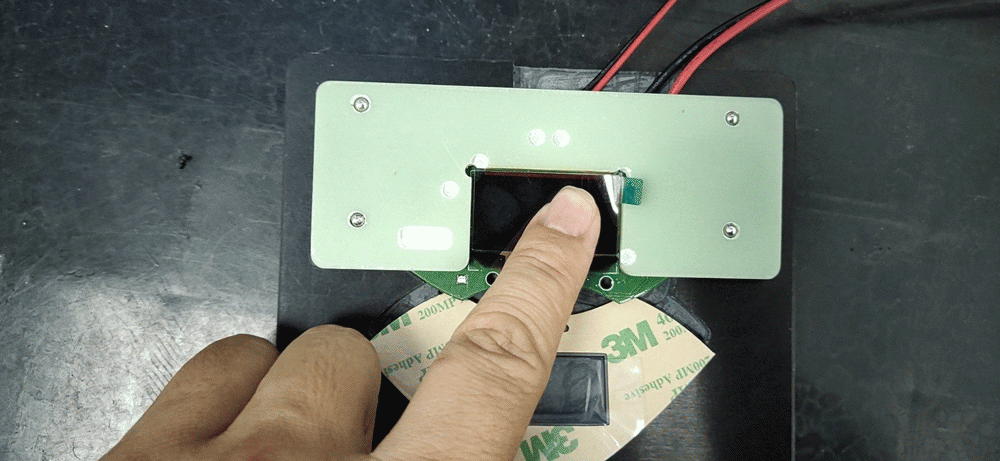

Above is a PCBA board that can’t be installed because of the OLED sticking problem. There is a “window” on the board by the designer, the same size as the OLED. We stuck the OLED with this window with error < 0.1mm (actually even not visible by eyes). As all OLED are stuck manually, in production it can’t be ensured there the error 0 (and also did not noticed that this position request needs to be so high). The bottom reason is there the mechanical design does not leave an error range, such as 0.1mm, to make it suitable for the OLED position errors.

But, indeed the OLED sticking with error can’t be installed and there all the cases are ready and can’t be modified. Debating on the reason& responsibility does not help in the store. Again, we Makerfabs can be the only one to solve this, that to re-stick the OLED without even a little error.

To solve this OLED sticking problem, Makerfabs did the following:

1. Manually take off the OLED from the sticker…

Very hard and high risk as the sticker really firm and OLED fragile… We have to do this all manually!

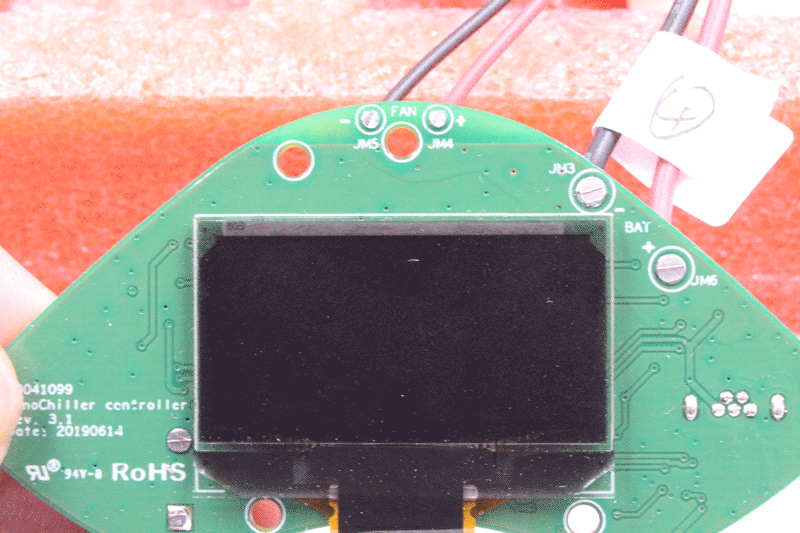

2. How to control the error to 0? Makerfabs engineers designed a fixture.

3. Handed over the final re-stick boards to the product assembly factory multiple around

If they still encounter the same problem again, we could think about it more.

4. Suggestion to Begin PCBA Mass Production

As the PCBA producer in China, Makerfabs always do more than PCBA production for customers, with this accident, Makerfabs suggestions to Makers& Startups who need multiple producers' cooperation, to begin the mass production:

1. It is much more complicated to make a final product with structure/mechanical/electronic, need not only experience on the design, but also on real production;

2. There're many problems that need to deal with in new product production, a designer should be very familiar with your producer in China, who will do what, and the bottom reason and who should be responsible when exceptions. A solution for this is authorizing someone/company, to coordinate all vendors/deal with all the exceptions. And he/she be your only vendor. Of course, a reliable& experienced agent is core important.

As a PCBA manufacturer in China for more than 6 years, it's true that Makerfabs encountered many different production problems, check this blog to see How Makerfabs Solve the Soldering Problem. Pls contact service@makerfabs.com if you have further questions and PCBA related requirements.

Previous

Previous